Adhering to the Code of Target Zero

At Superior Cementing, we prioritize the health, safety, and wellness of our employees, in full alignment with Superior Energy Services’ HSEQ policy. Established in 2012, our Target Zero Safety Management System provides the global framework to ensure compliance with health, safety, and environmental standards while reinforcing the two Shared Core Values of Safety and Citizenship.

Empowering Employees for Safety and Accountability

Employees are encouraged to take ownership of safety by exercising Stop Work Authority and are provided with the necessary tools, resources, and training to meet these expectations. Regular evaluations are conducted to assess compliance with safety metrics and to foster a culture of accountability and participation.

Commitment to Sustainability

We are committed to being a responsible operator and environmental steward, continuously seeking opportunities to enhance our Environmental, Social, and Governance (ESG) initiatives. Through ongoing risk assessments, Superior Cementing implements controls to mitigate potential hazards and environmental impacts. We strive to maintain operational excellence and accountability, ensuring that safety performance meets the expectations of customers and the community. This commitment to safety and sustainability is pivotal to our growth and success in an evolving industry.

Production Management System

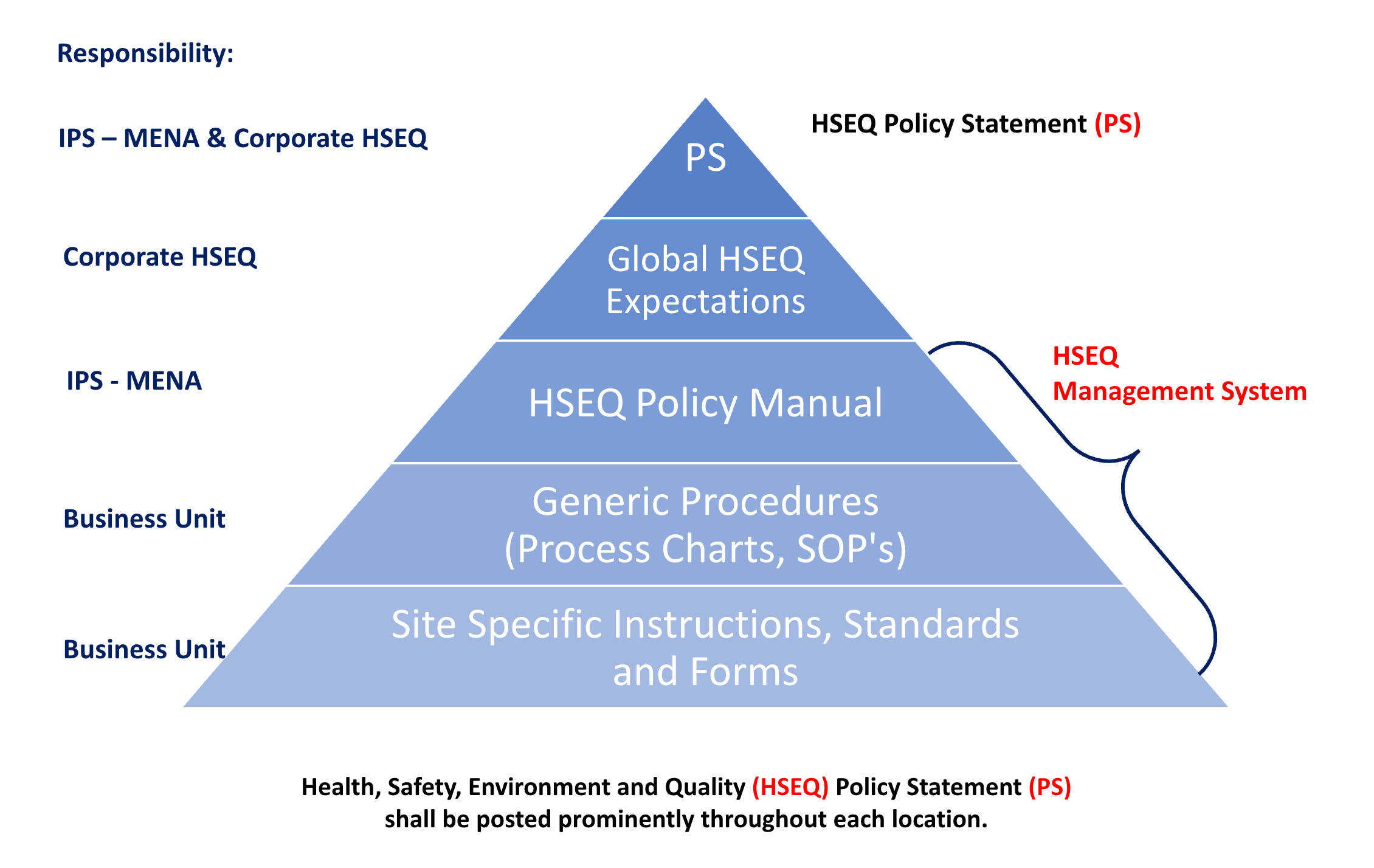

This management system is built upon the requirements defined in Superior's HSEQ Policy Statement and HSEQ Global Expectations, found on the Target Zero website. International Production Services - MENA' HSEQ Policies and HSEQ Manual, have been developed to comply with ISO-9001, ISO-14001, ISO-45001 and API Q2.

Equipment Maintenance Protocols

Superior Cementing uses Fiix, a cloud-based Computerized Maintenance Management System (CMMS), to support all equipment maintenance policies and activities. By streamlining workflows, Fiix empowers us to efficiently manage work orders, schedule preventive maintenance, and track asset performance. This proactively helps minimize equipment failures and downtime, which is vital in an industry where equipment reliability is critical.

Streamlined Maintenance and Inventory Control

In addition to optimizing maintenance strategies, Fiix provides robust inventory control features that ensure spare parts and supplies are readily available, reducing delays and controlling costs. With mobile accessibility, Fiix allows technicians to access and update work orders from any location, enhancing productivity and communication. The system also supports compliance by maintaining detailed records of maintenance activities, essential for meeting regulatory requirements and optimizing maintenance strategies.

Recognized for Excellence

HSE Excellence

- Kuwait Oil Company CEO's "HSE Excellence Award" (2022-2023)

- Gulf Cooperation Council "HSE Excellence Award" by the American Society of Safety Professionals, Kuwait Chapter (2023 & 2024)

- "A" rating on HSE Performance from Corporate HSE

Service Quality

Top Cementing Service Provider in Kuwait Oil Company's (KOC) rankings for 2024:

- Ranked #1 in Deep Drilling operations (out of 4 suppliers)

- Ranked #1 in Development Drilling operations (out of 6 suppliers)

Exceptional Support

KOC Appreciation Award for reliability in service delivery during the COVID-19 crisis- Recognized for seamlessly replacing unavailable competitors in cementing services, demonstrating commitment to reliability and continuity.